Onshoring Manufacturing: Why It’s Time to Rethink Offshoring

Onshoring Manufacturing: The Answer to Rising Costs and Delays

Does this sound familiar?

Your supply chain worked—until it didn’t.

Freight chaos. Rising costs. Slipping timelines. Your Go-To-Market (GTM) strategy is under pressure—and so are you.

At Kinetyc, we help manufacturers pivot to U.S. onshoring with speed, scale, and fewer surprises.

Let’s Be Honest: Offshoring Isn’t What It Used to Be

In the past, offshoring seemed like a no-brainer: lower labor costs, global access, and fast growth. But today’s reality looks different—and riskier. Here’s why:

- Freight unpredictability is still a planning nightmare — In 2025, ocean shipping remains volatile, with sudden rate changes, blank sailings (canceled or skipped vessel trips), and shifting tariffs making it difficult for companies to plan production or control landed costs when relying on overseas assembly (Supply Chain Dive).

- Disruption is now baseline — McKinsey’s 2024 survey of 88 senior supply chain leaders found that 90% experienced significant disruption, with many reevaluating their global sourcing strategies as a result (McKinsey).

- Executives are urgently reshaping supply chains — A Conference Board survey found that 85% of large-company executives plan significant supply chain changes, and 26% are actively exploring reshoring or localization strategies to bring production closer to key markets in response to global trade instability (Financial Times).

With challenges like these, scaling with confidence isn’t easy.

Let Kinetyc take the manufacturing load off your shoulders—so you can stop chasing stability and start building momentum.

Onshoring Manufacturing with Agility: We’ve Got Your Back

Onshoring doesn’t mean you need to build a factory from scratch or take on massive risk.

It means finding the right U.S. partner—one who can flex with your growth, reduce complexity, and help you scale intelligently.

That’s where Kinetyc comes in.

Meet Kinetyc: Your Easy Path to Adaptive Manufacturing

At Kinetyc, we believe onshoring manufacturing should be strategic—not stressful.

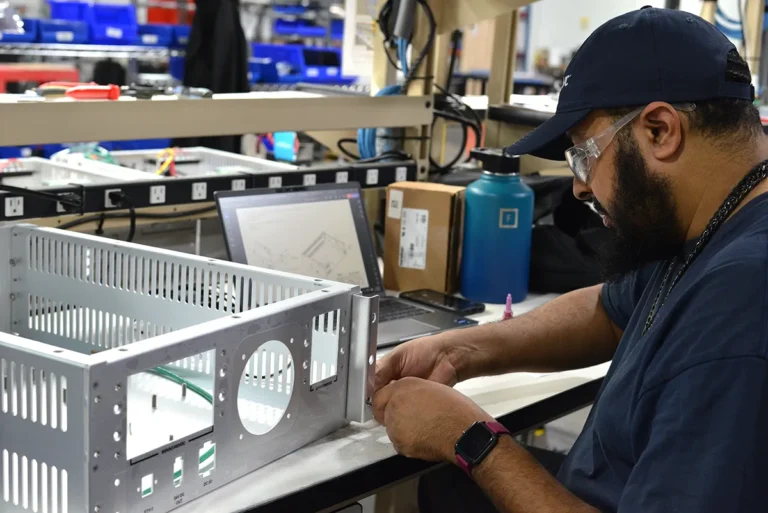

Our 100,000 sq. ft. facility in Wixom, Michigan is built to help companies scale without overextending.

We offer:

- Scalable production that flexes with your demand—whether you’re in startup mode or ramping for a major launch

- Speed to market through in-house 3D printing, laser cutting, and light assembly

- Space and capital solutions that let you expand without investing millions up front

- Advisory support from a team that’s passionate about helping companies pivot or reshore successfully

- Central U.S. location that cuts freight costs and lead times, giving you back control

Whether you’re rolling out a new product or reshoring existing lines, our adaptive manufacturing model moves at your pace.

We’ll Help You Bring Your Manufacturing Home—Without Breaking the Bank

Onshoring your manufacturing doesn’t have to be hard.

With Kinetyc, you get:

- Speed to market

- Scalability

- Strategic support

- U.S.-based resilience

All backed by a manufacturing partner committed to your long-term success.

Let’s Have a Conversation

Onshoring manufacturing isn’t just a backup plan anymore—it’s a strategic edge.

Let’s talk about how Kinetyc can help you bring your manufacturing home and scale smarter.

Contact us to explore what adaptive U.S. manufacturing looks like for your business—and how onshoring manufacturing can help you move forward with confidence.