What Does a Contract Manufacturer Actually Do? (And Why the Right One Changes Everything)

If you’re trying to bring a product to market—or scale one that’s already gaining traction—you’re carrying a quiet, constant pressure:

And somewhere in the middle of all that, there’s production.

At that point, most teams face a real decision: build manufacturing in-house, stitch together a network of vendors, or partner with someone who does this every day.

Each path comes with tradeoffs—and each carries risk. The real question is whether your path can scale with your business and continue to support it as your needs evolve.

That’s where a contract manufacturer enters the story. Some operate as vendors; others step in as true partners—and the difference matters more than most companies realize.

So what does a contract manufacturer actually do?

And why does the right one fundamentally change your ability to grow?

Let’s break it down.

Your Manufacturer Is Your Support. You Are the Hero in This Story

You’re the one:

You didn’t start your business to manage:

But if you’ve ever lived through a bad manufacturing partner, you know how fast those things can take over—and how distracting they become.

The Real Problem: Growth Breaks Rigid Manufacturing Models

Traditional manufacturing is often built for static demand.

Your business is not static.

Demand rises and falls. Environmental, governmental, and socio-economic forces can impact product delivery, revisions, and scope—leaving you vulnerable to unforeseen disruptions.

Left unchecked, those disruptions can wreak havoc on warehousing, delivery obligations, and sustainable inventory levels.

That mismatch creates familiar pain:

Growth becomes something you brace for instead of something you celebrate.

And that’s the wrong story.

What a Contract Manufacturer Actually Does

At its core, a contract manufacturer builds your product on your behalf under a formal agreement—so you don’t have to build and manage a factory, along with its many expenses and logistical considerations.

You keep:

That’s where your manufacturing partner comes in, providing:

You innovate, market, and sell. Your manufacturing partner manages production complexity and ensures reliable delivery.

A true contract manufacturing partner typically supports:

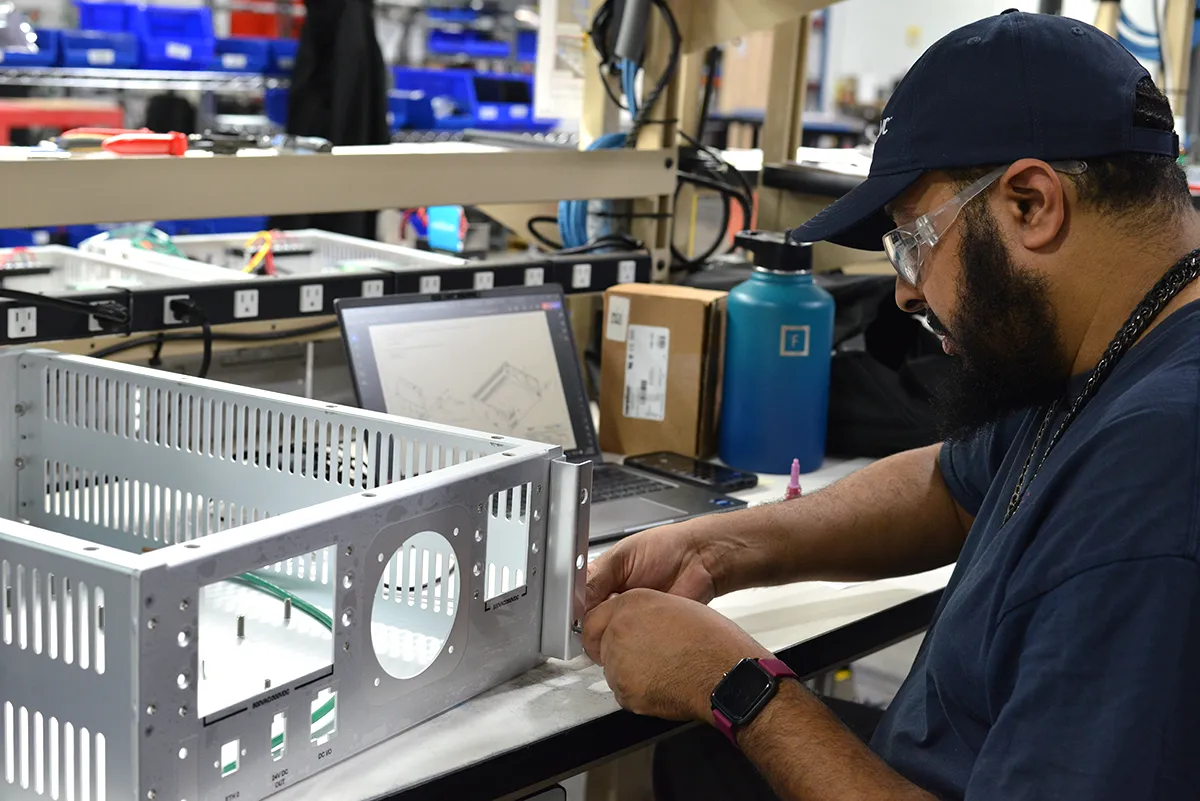

1. Production & Assembly

From component manufacturing to sub-assemblies and even complete finished products, manufacturers produce your product to specification using the tools, systems, and processes they operate every day.

2. Manufacturing Technologies Under One Roof

Instead of investing in expensive capital equipment yourself, you gain access to the capabilities of your manufacturing partner. Examples may include production-grade 3D printing, pellet extrusion, injection molding, precision laser cutting, and integrated assembly operations.

Having a partner can eliminate—or significantly reduce:

These benefits alone are enough to make companies of all sizes consider partial—or even full—outsourcing of their products.

3. Supply Chain & Material Flow

Managing supply chains can be a real headache. When a single link breaks, production schedules and customer commitments are often the first to suffer. Sustained instability can threaten not just a product—but the business behind it.

Working with a contract manufacturer can help absorb:

In short, you stop juggling dozens of vendors—and regain control.

4. Quality Systems & Process Control

This is what protects your reputation:

Working with an ISO-certified manufacturer helps ensure quality stops being a gamble—and becomes a system. Kinetyc is proudly ISO 9001 certified and stands ready to show the difference a quality-driven, adaptive manufacturing approach makes.

5. Scaling Without Breaking

This is where everything either works… or collapses.

The right contract manufacturing partner allows you to:

With the right partner, growth stops being something you survive—and becomes something you can plan for.

Where Kinetyc Changes the Story: Adaptive Manufacturing

At Kinetyc, manufacturing isn’t rigid.

It’s adaptive by design.

That means:

With a 100,000 sq. ft. facility in Wixom, Michigan and a multi-technology manufacturing ecosystem under one roof, Kinetyc is built to support:

All within a unified quality and production system.

That’s what Adaptive Manufacturing really means:

Your manufacturing scales at the same pace as your business—without destabilizing it.

Kinetyc focuses on long-term manufacturing partnerships built on flexibility, quality, and shared growth.

Why Kinetyc’s Adaptive Manufacturing Model Matters

Because your business will change.

Your demand will shift.

Your markets will evolve.

And when that happens, you need:

Kinetyc is the contract manufacturing partner you can’t outgrow—or outpace. Whether scaling up or down, we adapt so you can focus on the parts of the business that make you a market leader.

Is Kinetyc the Right Manufacturing Partner for You?

If you’re:

Then a short conversation can help clarify your next step.

Contact Kinetyc to talk through your product, your production goals, and whether Adaptive Manufacturing is the right fit.

No pressure. Just clarity.